Turning Pure Experience into a Profitable Process.

For over 50 years, W.A. Tompkins has specialized in providing quality engineered solutions for sanitary process systems and equipment. As a result, we’ve developed an in-depth understanding of the immediate requirements for the industries we serve — along with the ability to help anticipate our customers’ needs and opportunities down the line.

While continuing to invest in the development of new methodologies, W.A. Tompkins stays abreast of the latest technologies. This helps our valued customers to keep their processes on the leading edge for performance and purity.

Providing the Finest Lines in the Industry.

New, Used or Reconditioned.

Selection and procurement of proven brand-name equipment is just one facet of what we do. W.A. Tompkins provides exceptional support across the entire process lifecycle — from concept through startup and beyond. This includes the expertise to install high-purity stainless steel piping. The ability to restore and recondition used equipment to pristine working condition. And the installation of CIP systems to keep processes running cleanly and efficiently.

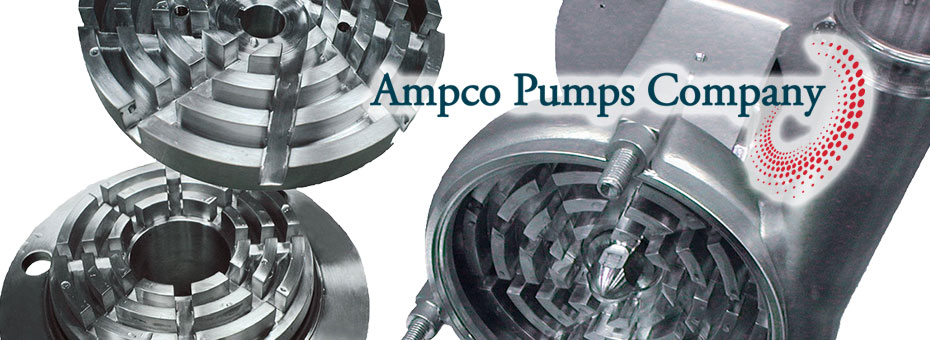

SPX APV Homogenizer Parts and Service

When Equipment Reliability Means Everything ….

You can Trust W.A. Tompkins

With optimum process performance and reliability built in – SPX replacement parts represent remarkable value for money and are the only serious choice when it comes to reliability and peace of mind.

Refurbishment

Improved plant flexibility and the protection of your existing investments has been one of our key objectives for many years. The refurbishment of critical plant components can often contribute to improved plant performance, minimise the use of costly resources, such as energy and reduce waste of valuable ingredients. Improvements of this type also help to preserve the environment and support the need to meet increasingly stringent regulations.

Improved plant flexibility and the protection of your existing investments has been one of our key objectives for many years. The refurbishment of critical plant components can often contribute to improved plant performance, minimise the use of costly resources, such as energy and reduce waste of valuable ingredients. Improvements of this type also help to preserve the environment and support the need to meet increasingly stringent regulations.